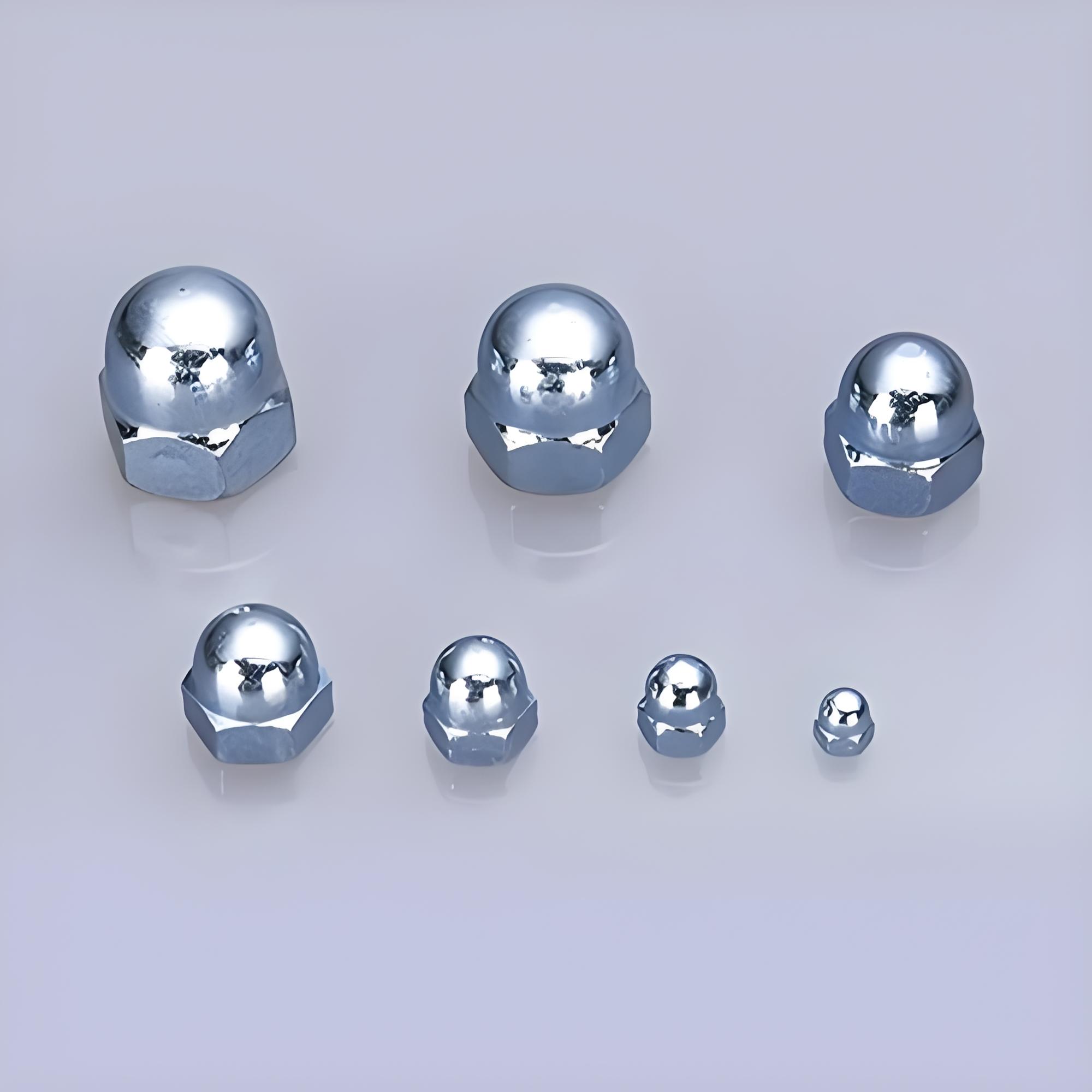

DIN1587/Hexagon cap nut

diameter: 3 4 5 6 8 10 12 14 16 20 22 24 27 30 33 36

material: 304 316 carbon steel

thread form: Coarse thread Fine thread and so on

surface finishing: natural coating black galvanizing Dacromet coating and so on

The hexagonal cap nuts according to DIN1587 can be classified by material as follows:

1. Stainless Steel: Such as AISI304 (corresponding to 1.4301 in DIN EN 10088-1), AISI316 (corresponding to 1.4401 in DIN EN 10088-1), and AISI316L (corresponding to 1.4404 in DIN EN 10088-1).

2. Steel: Including C15E carbon steel in ASTM A108/ASME SA108/DIN EN 10263-2, C45E carbon steel in ASTM A29/ASME SA29/DIN EN 10263-2, and 42CrMo4 alloy steel in ASTM A193/ASME SA193/DIN EN ISO 898-1.

3. Brass: For example, CuZn39Pb3 brass in ASTM B16/ASME SB16/DIN EN 12164, CuZn40Pb2 brass in ASTM B21/ASME SB21/DIN EN 12164, and CuZn37 brass in ASTM B455/ASME SB455/DIN EN 12165.

4. Plastic: Commonly, polyamide (PA), that is, nylon, which belongs to thermoplastic materials.https://pangjinfasteners.com/about-us.html

The surface treatment methods of hexagonal cap nuts according to DIN1587 mainly include the following:

1. Zinc plating: It includes blue-white zinc plating and yellow zinc plating, etc. Zinc plating can form a zinc layer on the surface of the nut, playing a role in preventing corrosion. Blue-white zinc has a more beautiful appearance, and yellow zinc has relatively better corrosion resistance.

2. Blackening: Also known as oxidation treatment, it makes a black oxide film form on the surface of the nut, which can prevent rust to a certain extent. At the same time, it gives the nut a black appearance and is often used in occasions where the appearance requirements are not high but a certain anti-corrosion ability is needed.

3. Whitening: Generally, it is for nuts made of stainless steel. Through chemical treatment and other methods, the surface of the nut can be made cleaner and brighter, improving the appearance texture.

4. Hot-dip galvanizing: Immerse the nut in the molten zinc liquid, so that a relatively thick and dense zinc layer is formed on the surface of the nut. It has good corrosion resistance and is suitable for harsh environments such as outdoors.

5. Dacromet coating: It is a new type of corrosion-resistant coating, which has good salt spray corrosion resistance and high-temperature oxidation resistance, and can effectively protect the nut matrix and extend the service life.

1. About package

1.1 In our daily production operations, we always maintain a rigorous and scientific attitude towards the product packaging process. When it comes to selecting materials for the inner packaging of products, we typically use plastic films, plastic bags, or plastic trays. Thanks to their excellent sealing properties and corrosion resistance, these materials can effectively protect products and perform the functions of moisture prevention and rust prevention remarkably well. Especially for those fastener products with high manufacturing precision or those that are relatively fragile and vulnerable, we will additionally use cushioning materials with excellent shock absorption performance, such as foam plastics and sponges, to further enhance the protection. In this way, we can avoid product damage caused by various collisions and jolts during transportation, ensuring the integrity and quality of products to the greatest extent. Regarding the outer packaging, we usually choose corrugated cardboard boxes, wooden cases, or plywood cases. Corrugated cardboard boxes are lightweight and cost-effective, making them suitable for fasteners with relatively light weights. Wooden cases and plywood cases have high strength, which not only allows them to bear heavier loads but also enables them to meet the fumigation requirements for export packaging, making them ideal for heavy-duty or vulnerable fasteners.

1.2 In addition, we attach great importance to the personalized needs of each customer and are committed to providing customized packaging services. If customers have unique design requirements for the color, pattern, and size of the packaging, or if they expect to print exclusive brand logos on the packaging to enhance their brand image, we will go all out, mobilize various resources of the company, and make every effort to meet each special requirement of the customers. We strive to create unique packaging solutions for customers that are in line with their brand concepts and market positioning.

2.About payment

Our company uniformly adopts T/T (Telegraphic Transfer) as the payment method. For regular orders, a 30% advance payment is required at the time of placing the order to initiate the order process. The remaining 70% balance must be fully settled before the goods are loaded onto the vehicle to ensure a seamless connection between the payment transfer and the goods transportation process.

In the case of customized products, considering the particularity of their production, the advance payment proportion is adjusted to 30% - 50%, which needs to be paid upon finalizing the customized details and signing the contract. The remaining balance is also required to be paid off before the goods are loaded. Only when the balance is cleared can the goods be guaranteed to be delivered to your designated location on time and smoothly, avoiding any possible delays or disputes.

3.About Delivery & shipment

For in-stock products, with the support of our efficient logistics distribution system and internal coordination mechanism, we promise to complete the delivery within 10 days, enabling you to obtain the desired goods promptly. As for customized products, since they need to be produced according to specific specifications and requirements, involving multiple processes such as design confirmation, raw material procurement, and production, we will generally complete the delivery within one month, ensuring that you can receive the customized products that meet your needs as scheduled.