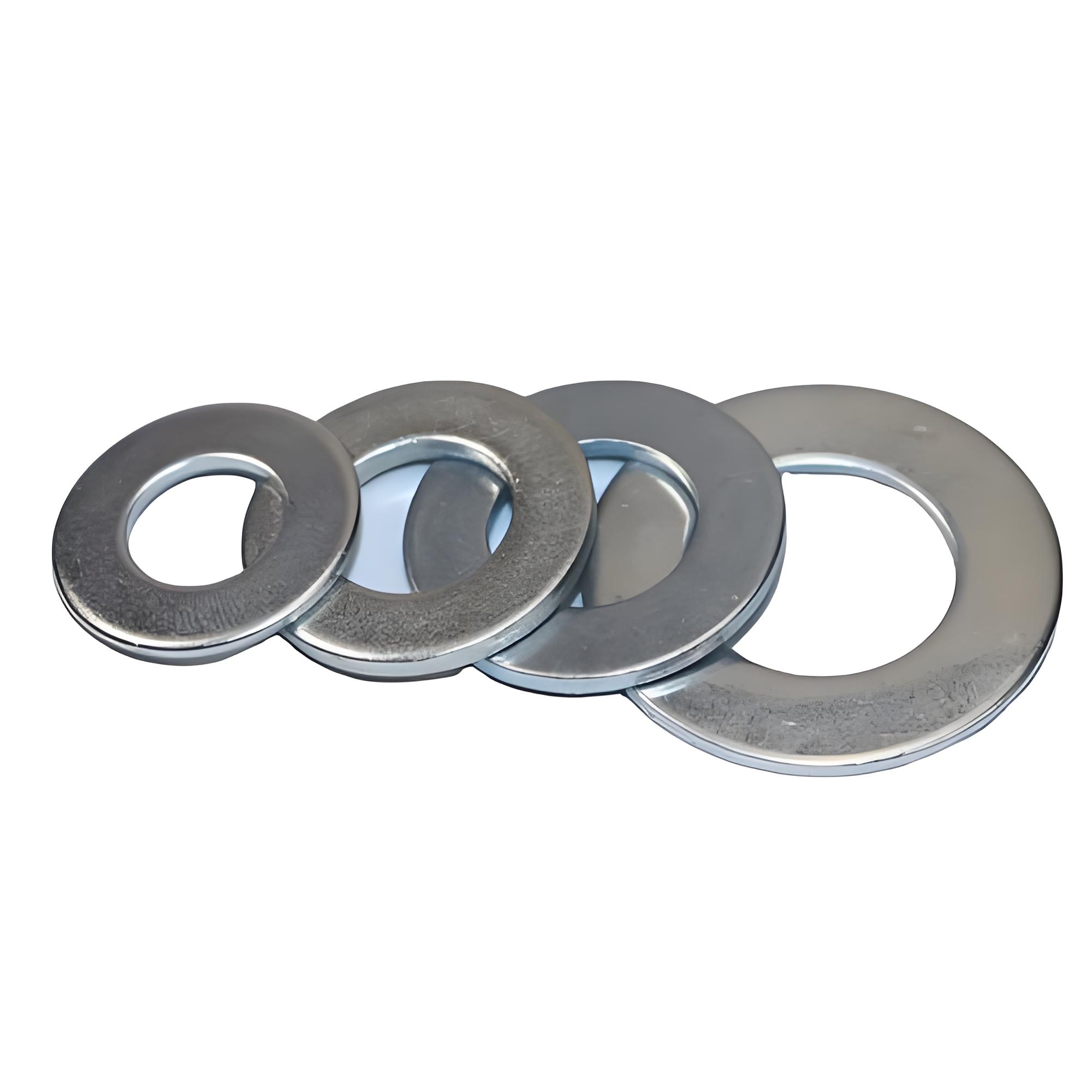

DIN127(B)

The information of DIN127(B) is as follows.

diameter: 2 2.5 3 4 5 6 8 10 12 14 16 18 20 22 24 27 30 33 36

material: 304 carbon steel copper

DIN127(B)spring washers can be classified according to their performance into the following categories:

Ordinary Type

– It has basic anti-loosening performance and is suitable for general mechanical connection occasions. It has relatively weak resistance to vibration and impact and can maintain the reliability of the connection in a static or environment with small vibrations, such as the connection of components of ordinary machine tools.

Corrosion-resistant Type

– Made of corrosion-resistant materials such as stainless steel, it can maintain good performance in a humid environment or in the presence of corrosive gases or liquids, preventing the washer from failing due to corrosion and thus ensuring the stability of the connection. It is applicable to the connections in chemical equipment, marine engineering equipment, etc.

High-strength Type

– Usually made of high-quality alloy steel or materials that have undergone special heat treatment, it has high strength and elastic limit, and can withstand large axial tensile forces and vibration loads. It is suitable for occasions with high requirements for connection strength, such as heavy machinery and automobile engines.

Heat-resistant Type

– Manufactured from high-temperature resistant materials, such as heat-resistant alloy steel, etc., it can maintain good elasticity and anti-loosening performance in a high-temperature environment, and will not lose its elasticity or deform due to high temperatures. It is often used for the connections of high-temperature equipment such as engine exhaust systems and industrial high-temperature furnaces.

– 70# Spring Steel: It has a balanced strength and toughness. After heat treatment, it can obtain good elasticity and hardness, and is suitable for occasions with high requirements for elasticity and stability.

Stainless Steel Category

– 304 Stainless Steel: It has good corrosion resistance and oxidation resistance, can maintain stable performance in a variety of environments, and is not easy to rust. It is suitable for fields with high requirements for hygiene and corrosion resistance, such as food processing, medical devices, and chemical equipment.

– 316 Stainless Steel: It has higher corrosion resistance than 304 stainless steel, especially in terms of resistance to chloride corrosion. It is often used in marine environments, coastal areas, and some equipment connections in harsh corrosive environments such as strong acids and alkalis.

Alloy Steel Category

By adding alloying elements such as chromium, nickel, and molybdenum to carbon steel, comprehensive properties such as higher strength, hardness, toughness, and corrosion resistance can be obtained. It is suitable for some special occasions with extremely high requirements for washer performance, such as aerospace and high-end machinery manufacturing.

Copper and Copper Alloy Categoryhttps://pangjinfasteners.com/about-us.html

– Pure Copper: It has good electrical conductivity and thermal conductivity, and its texture is relatively soft. It is used in the connection of some electrical equipment, which can avoid damage to the contact surface and also has a certain anti-loosening effect.

– Brass: It is a copper-zinc alloy, which has good corrosion resistance and mechanical properties. Its elasticity and strength are moderate, and it can be used in some occasions where the anti-loosening requirements are not particularly high, but good corrosion resistance is required.

The surface treatment methods of DIN127(B) spring washers mainly include the following:

1. Blackening Treatment

2. Galvanizing Treatment

3. Hot-dip Galvanizing Treatment

4. Nickel Plating Treatment:

1. About package

1.1 In our daily production operations, we always maintain a rigorous and scientific attitude towards the product packaging process. When it comes to selecting materials for the inner packaging of products, we typically use plastic films, plastic bags, or plastic trays. Thanks to their excellent sealing properties and corrosion resistance, these materials can effectively protect products and perform the functions of moisture prevention and rust prevention remarkably well. Especially for those fastener products with high manufacturing precision or those that are relatively fragile and vulnerable, we will additionally use cushioning materials with excellent shock absorption performance, such as foam plastics and sponges, to further enhance the protection. In this way, we can avoid product damage caused by various collisions and jolts during transportation, ensuring the integrity and quality of products to the greatest extent. Regarding the outer packaging, we usually choose corrugated cardboard boxes, wooden cases, or plywood cases. Corrugated cardboard boxes are lightweight and cost-effective, making them suitable for fasteners with relatively light weights. Wooden cases and plywood cases have high strength, which not only allows them to bear heavier loads but also enables them to meet the fumigation requirements for export packaging, making them ideal for heavy-duty or vulnerable fasteners.

1.2 In addition, we attach great importance to the personalized needs of each customer and are committed to providing customized packaging services. If customers have unique design requirements for the color, pattern, and size of the packaging, or if they expect to print exclusive brand logos on the packaging to enhance their brand image, we will go all out, mobilize various resources of the company, and make every effort to meet each special requirement of the customers. We strive to create unique packaging solutions for customers that are in line with their brand concepts and market positioning.

2.About payment

Our company uniformly adopts T/T (Telegraphic Transfer) as the payment method. For regular orders, a 30% advance payment is required at the time of placing the order to initiate the order process. The remaining 70% balance must be fully settled before the goods are loaded onto the vehicle to ensure a seamless connection between the payment transfer and the goods transportation process.

In the case of customized products, considering the particularity of their production, the advance payment proportion is adjusted to 30% - 50%, which needs to be paid upon finalizing the customized details and signing the contract. The remaining balance is also required to be paid off before the goods are loaded. Only when the balance is cleared can the goods be guaranteed to be delivered to your designated location on time and smoothly, avoiding any possible delays or disputes.

3.About Delivery & shipment

For in-stock products, with the support of our efficient logistics distribution system and internal coordination mechanism, we promise to complete the delivery within 10 days, enabling you to obtain the desired goods promptly. As for customized products, since they need to be produced according to specific specifications and requirements, involving multiple processes such as design confirmation, raw material procurement, and production, we will generally complete the delivery within one month, ensuring that you can receive the customized products that meet your needs as scheduled.